Polyester is a versatile synthetic fiber widely used across various industries due to its unique properties.

1. Durability and Strength

- High Tensile Strength: Polyester fibers are exceptionally strong, making them ideal for applications requiring robust materials, such as industrial textiles, ropes, and conveyor belts.

- Abrasion Resistance: Polyester withstands wear and tear, ensuring longevity in products like tire cords, geotextiles, and heavy-duty fabrics.

- Low Stretch: Its low elasticity ensures dimensional stability, critical for precision in industrial processes.

2. Cost-Effectiveness

- Affordable Production: Polyester is relatively inexpensive to produce compared to natural fibers like cotton or wool, making it a cost-effective choice for large-scale industrial use.

- Low Maintenance: Products made from polyester require minimal upkeep, reducing operational costs in industries like automotive and construction.

3. Chemical and Environmental Resistance

- Moisture Resistance: Polyester is hydrophobic, repelling water and resisting mold, mildew, and bacterial growth, which is advantageous in industries like marine, agriculture, and outdoor equipment manufacturing.

- Chemical Stability: It resists degradation from acids, oils, and most chemicals, making it suitable for industrial filters, protective clothing, and chemical processing equipment.

- UV Resistance: Polyester maintains integrity under prolonged sun exposure, ideal for outdoor applications like awnings and tarps.

4. Versatility and Customization

- Wide Range of Forms: Polyester can be engineered into fibers, films, resins, or foams, catering to diverse industrial needs, from packaging (PET films) to insulation (polyester foam).

- Dyeability and Printability: It accepts dyes and prints well, enabling customization for branding or aesthetic purposes in industries like fashion and automotive upholstery.

- Blending Capability: Polyester blends easily with other fibers, enhancing properties like flexibility or softness for specific industrial requirements.

5. Thermal and Electrical Properties

- Heat Resistance: Polyester retains its shape and strength at high temperatures, making it suitable for insulation materials, automotive parts, and fire-resistant fabrics.

- Electrical Insulation: Its low conductivity makes it valuable in the electronics industry for insulating cables and components.

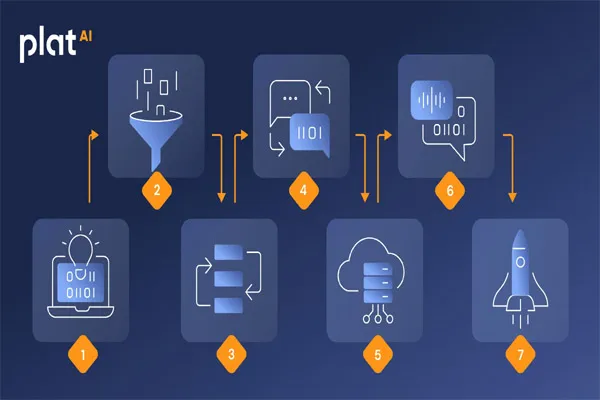

6. Recyclability and Sustainability

- Recyclable: Polyester, especially PET, is highly recyclable, supporting sustainable practices in industries like packaging and textiles. Recycled polyester (rPET) is used in bottles, clothing, and industrial fabrics.

- Energy Efficiency: Producing recycled polyester consumes less energy than virgin polyester, reducing the environmental footprint in industries adopting green practices.

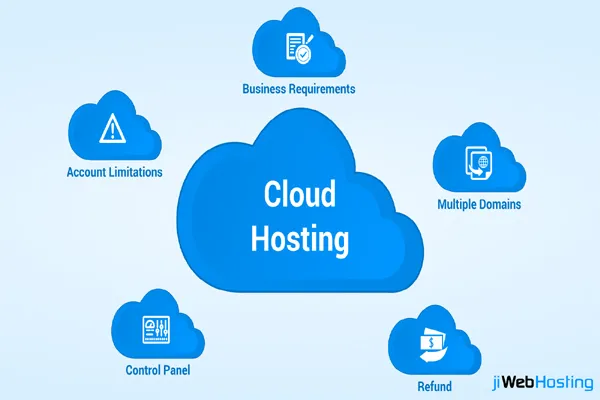

7. Applications Across Industries

- Textile Industry: Used in apparel, upholstery, and technical textiles due to its strength and wrinkle resistance.

- Automotive Industry: Employed in seat belts, airbags, and tire reinforcements for its durability and safety features.

- Construction: Geotextiles and roofing membranes benefit from polyester’s weather resistance and strength.

- Packaging: PET polyester is widely used for bottles, containers, and films due to its clarity, strength, and recyclability.

- Medical Industry: Polyester’s biocompatibility and sterilizability make it suitable for sutures, implants, and medical textiles.