Material strength refers to a material's ability to withstand applied forces without deformation, fracture, or failure. It is a measure of the material's mechanical properties under various types of stress, such as tension, compression, shear, or torsion.When selecting materials for engineering, construction, manufacturing, or other applications, two critical factors to consider are material strength and material viability. While these terms may seem related, they refer to different aspects of a material's suitability for a given purpose.

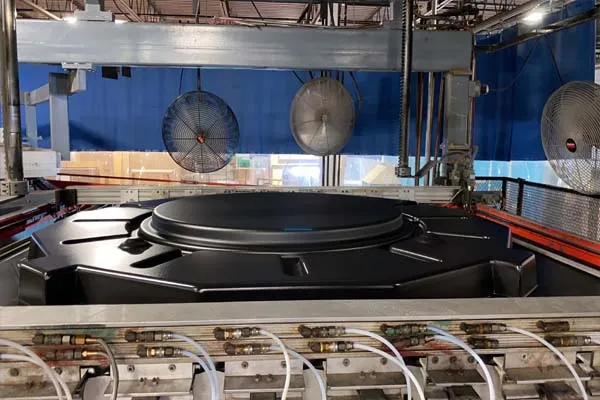

- Testing Methods: Common tests include tensile testing, compression testing, and hardness testing (e.g., Rockwell or Vickers scales).

- Units: Strength is typically measured in Pascals (Pa), Megapascals (MPa), or pounds per square inch (psi).

- Example: Steel has high tensile strength (400–550 MPa for mild steel), making it ideal for structural applications, while rubber has lower tensile strength but high elasticity.

Material viability refers to the overall suitability of a material for a specific application, considering factors beyond just mechanical strength. It encompasses practical, economic, environmental, and performance-related considerations to determine if a material is appropriate for its intended use.

Key Aspects of Material Viability:

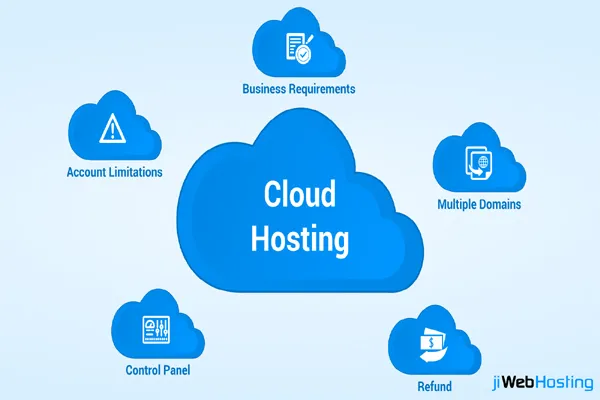

- Cost: Is the material affordable within the project’s budget?

- Availability: Is the material readily available or subject to supply chain constraints?

- Durability: How well does the material resist wear, corrosion, or degradation over time?

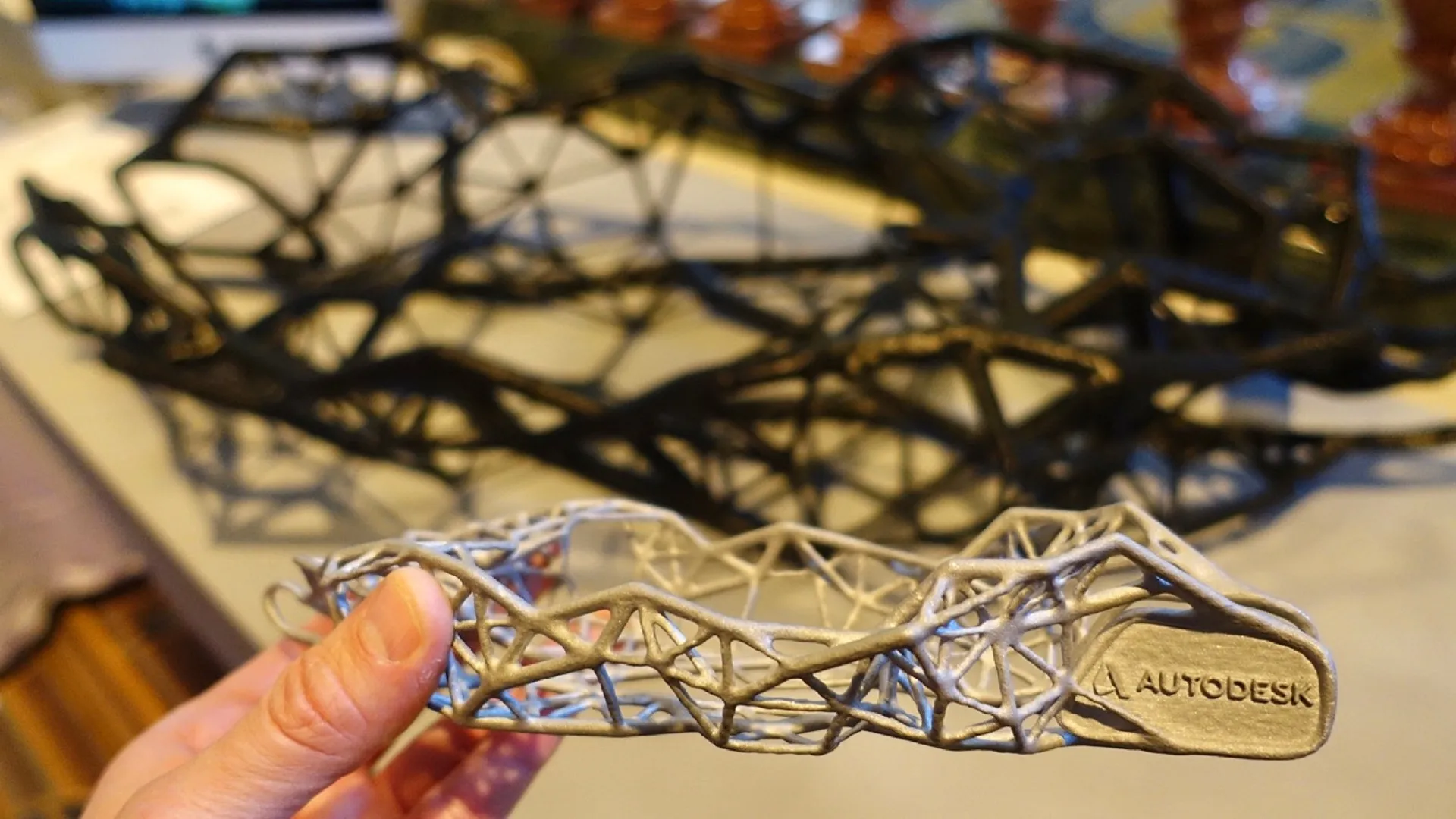

- Manufacturability: Can the material be easily processed, shaped, or assembled?

- Environmental Impact: Is the material sustainable, recyclable, or environmentally friendly?

- Compatibility: Does the material perform well in the intended environment (e.g., temperature, humidity, chemical exposure)?

- Regulatory Compliance: Does the material meet industry standards or regulations?

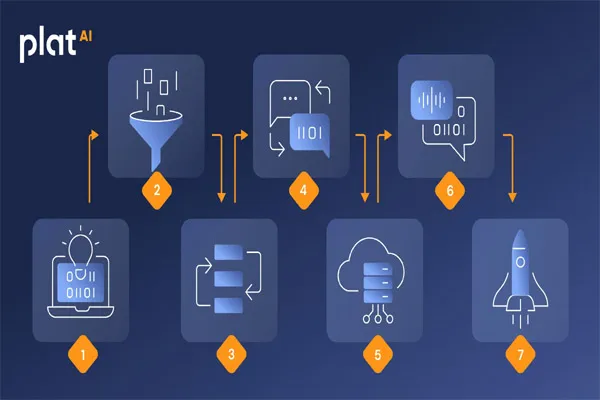

- Lifecycle Analysis: Assess the material’s performance from production to disposal.

- Cost-Benefit Analysis: Compare the material’s performance against its cost and availability.

- Environmental Testing: Evaluate how the material performs under specific conditions, such as extreme temperatures or corrosive environments.

- Example: Aluminum is viable for aerospace applications due to its lightweight nature, corrosion resistance, and availability, but it may not be viable for low-budget projects due to its cost.