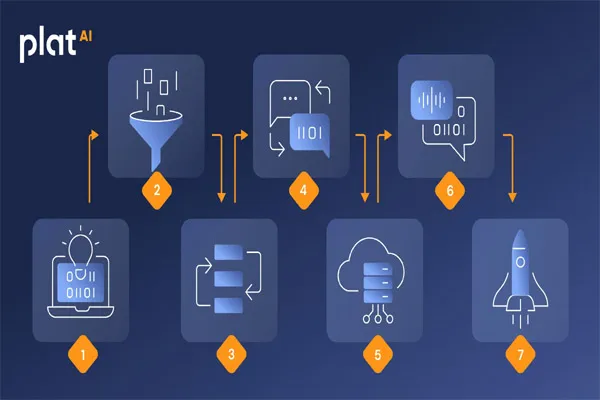

1. Creating a Digital Model:

- The first step in 3D printing is designing a 3D model using computer-aided design (CAD) software. These models can also be created by scanning an existing object or downloading a pre-made design from online repositories.

2. Slicing the Model:

- The 3D model is then sliced into thin horizontal layers using slicing software. This software converts the model into instructions (G-code) that the 3D printer can follow. Each slice represents a cross-sectional layer of the final object.

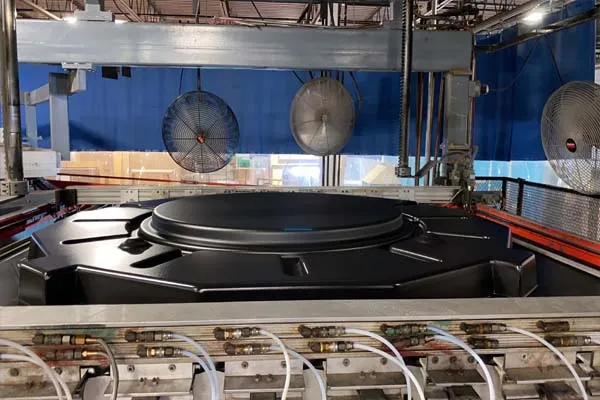

3. Setting Up the 3D Printer:

- The 3D printer is prepared by loading the appropriate material, which could be plastic, resin, metal, or even food, depending on the printer type. Common materials include PLA, ABS, and PETG for plastic printing.

4. Printing Process:

- The printer starts at the bottom of the object and builds it up layer by layer. The material is extruded through a nozzle (in Fused Deposition Modeling, FDM) or solidified by a laser (in Stereolithography, SLA). Each layer fuses to the layer below it as the material hardens or cools.

5. Post-Processing:

- Once printing is complete, the object may require post-processing, such as removing support structures, sanding, or curing (especially in resin-based printing). This step ensures the object has the desired finish and strength.

6. Final Product:

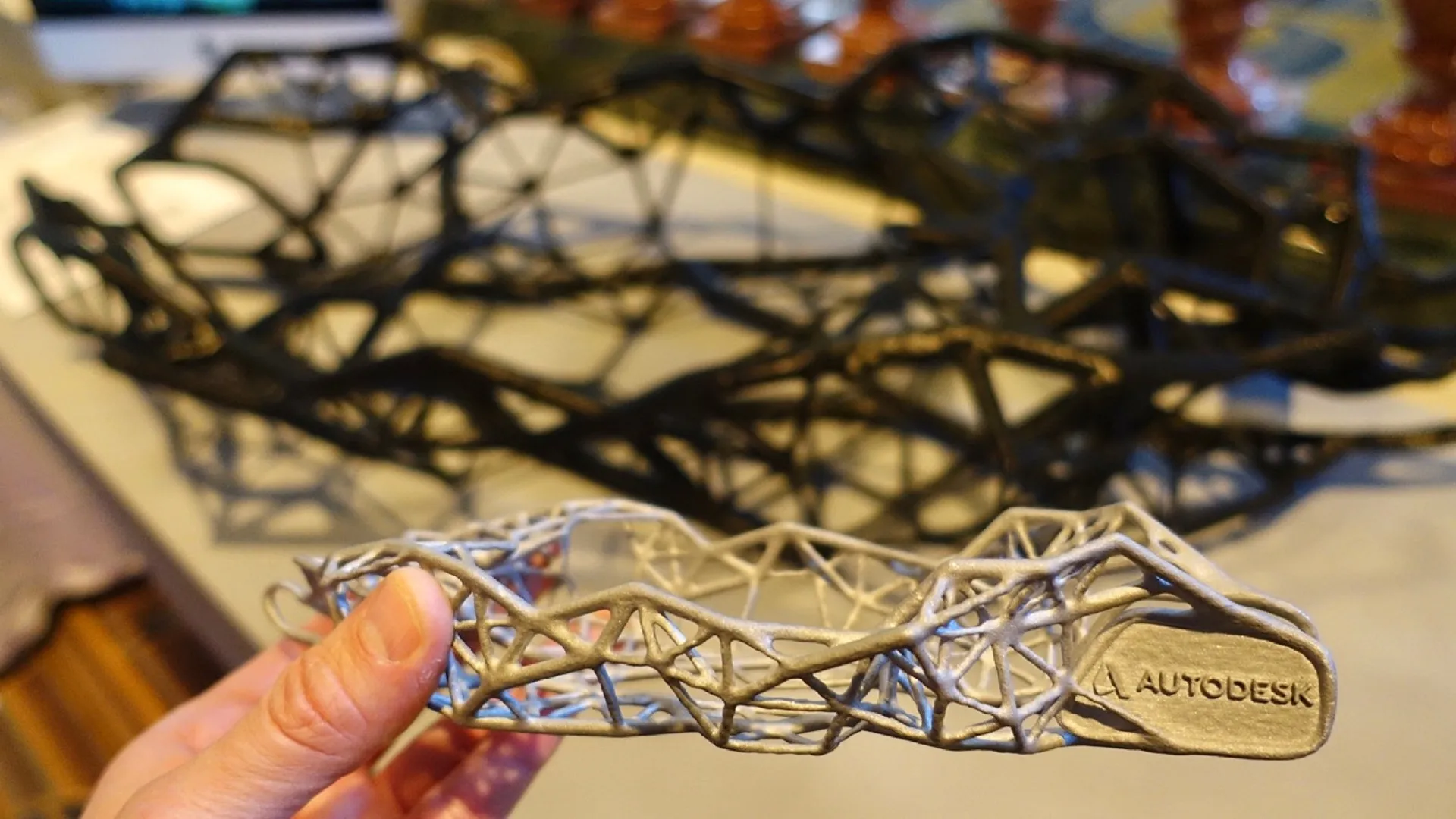

- The result is a fully formed 3D object that can be used as is or further modified. Depending on the application, 3D printed objects can range from simple prototypes to complex functional parts used in industries like aerospace, automotive, healthcare, and more.

Common 3D Printing Technologies:

- Fused Deposition Modeling (FDM): The most common type, which involves melting and extruding thermoplastic filament.

- Stereolithography (SLA): Uses a laser to cure liquid resin into hardened plastic.

- Selective Laser Sintering (SLS): Fuses powdered material (like nylon or metal) using a laser.

- Digital Light Processing (DLP): Similar to SLA but uses a digital light projector screen to flash a single image of each layer all at once.

3D printing is versatile, allowing for rapid prototyping, custom designs, and even the creation of complex geometries that would be difficult or impossible with traditional manufacturing methods.